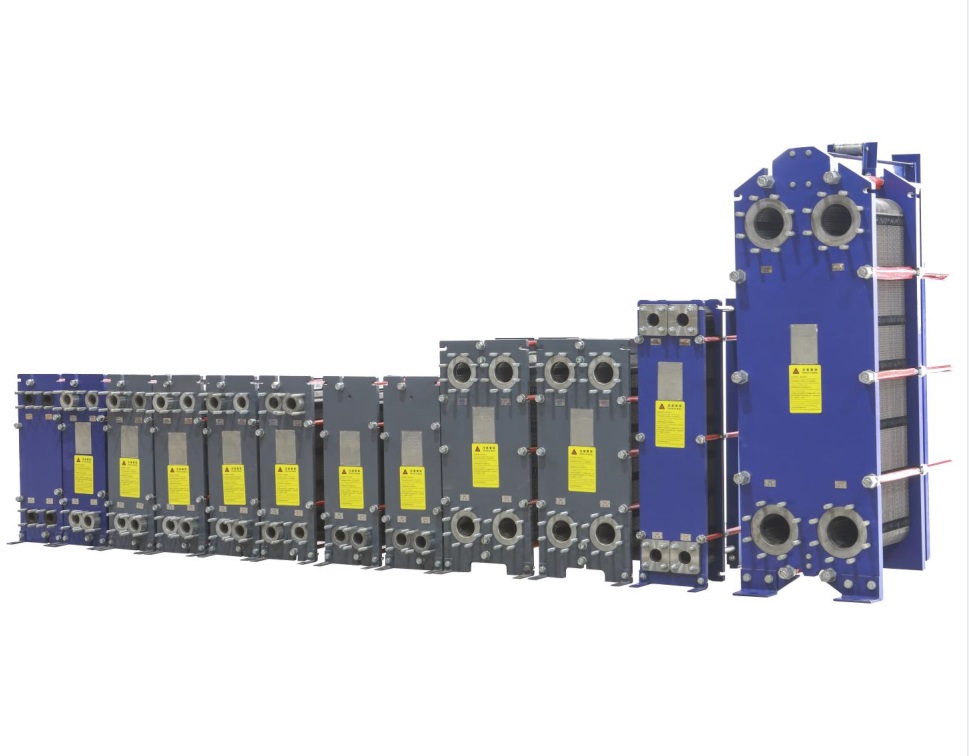

Product Introduction

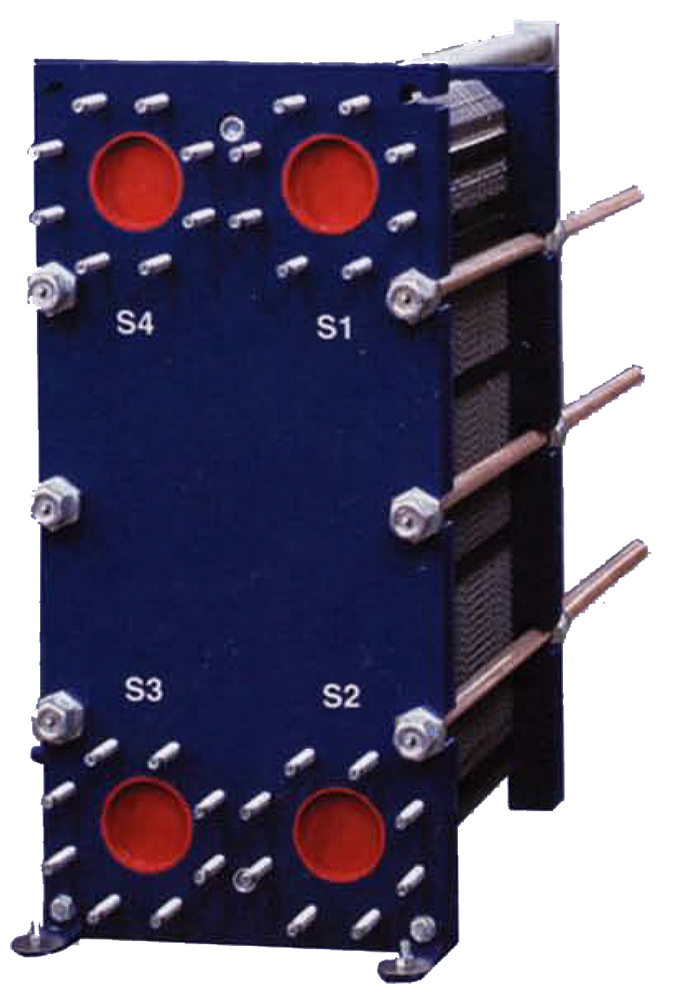

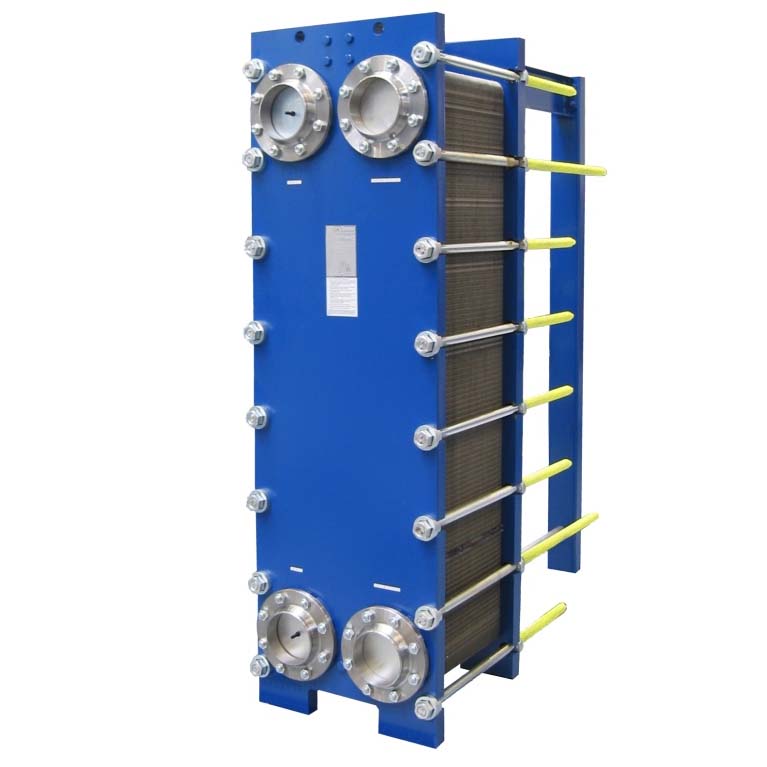

Alfalaval Plate heat exchanger

1.Frame material : commonly carbon steel paint ,carbon inner with stain steel out surface,Pure stain steel frame

2.Port: stud bolts with lining,selding neck flange,lapped flange,lapped flange with plain collar.

3.Plate material & thickness: Commonly AISI304/316/Ti plate 0.5/0.6mm

4.Gasket material : EPDM&NBR&FPM or others.(Most commly use is EPDM)

5.OEM&ODM

6.we offer perfect after-sale service system for repair and training.

7.We offer professional technology selection service,free service to help choose Appropriate models for you.

8.Our products are mainly to many countries,such as Pakisitan,India,Malaysia,Russia,Austrilia,Vietnam,Spain and so on.

9.Packing size: standard export wooden packing or steel frame packing.

10.Weight and packing size:we offer specized Chinese and English calculation books.

10.Our MOQ:1pcs Nearby Port:Shanghai we do EXW,FOB,CIF

11.100% in advance before shipment.Payment termsTT/LC.

We sincerely wish to be your china best parter,Our Goal is to become the heat exchanger service to responed you at any time!

| Name | Plate Heat Exchanger | |

| Brand | Alfa-laval | |

| MODEL | M/T/TL | |

| Plate material |

Stainless steel (AISI304,AISI316) titanium and titanium palladium (Ti, ti-pd) ,20Cr,18Ni,6Mo(254SMO), nickel (Ni)HASTELLOY alloy |

|

| Gaster material | NBR,HNBR, EPDM, FPM, CR, Viton | |

| Frame material | Stainless AISI304/AISI316 or Q235B etc | |

| Connect material | NBR,HNBR,EPDM,stainless AISI304/316 etc | |

| Advantage |

1.Sealing gasket is not exposed 2. Advanced plate structure 3. Advanced framework structure 4. Solid sheet thickness |

|

| Application: |

Widely used in petroleum industry, power station, solar photovoltaic, electronic industry, papermaking industry, textile industry, chemical industry, Marine and engine, hvac, food industry, oil processing, metallurgy industry, etc |

|

| Sealing material: | adapt temperature | Suitable for fluid |

| NBR | -15~+120℃ | Water, sea water, cooking oil, salt water |

| HNBR | -15~+140℃ |

High temperature mineral oil, high temperature water |

| EPDM | -25~+170℃ | Hot water, water vapor, acid, alkali |

| Viton | -5~+130℃ | Acid, alkali, fluid |

| Plate material | Suitable for fluid | |

| Stainless(AISI304,AISI316): | Clean water, river water, cooking oil, mineral oil | |

| Ti,Ti-Pd: | Sea water, salt water, salt | |

| 20Cr,18Ni,6Mo(254SMO): | Dilute sulfuric acid, dilute salinized water solution, inorganic water solution | |

| Ni: | High temperature, high viscosity caustic soda | |

| HASTELLOY: | Concentrated sulfuric acid, hydrochloric acid, phosphoric acid | |

Alfa-laval plate-heat-exchanger Specification:

| Model | Connection | QMAX | PMAX | TEST PMAX | Surface max | W | H | L |

| DN | (m³/H) | Bar | Bar | ㎡ | mm | mm | mm | |

| M3 | 32 | 14 | 16 | 21 | 3 | 180 | 490 | 700 |

| M6 | 50 | 45 | 25 | 33 | 37 | 320 | 930 | 1410 |

| M6M | 50 | 45 | 25 | 33 | 35 | 320 | 930 | 1610 |

| M10B | 100 | 190 | 25 | 33 | 100 | 460 | 1084 | 2400 |

| M10M | 100 | 190 | 25 | 33 | 60 | 460 | 1084 | 2400 |

| TL10B | 100 | 190 | 30 | 39 | 250 | 480 | 1981 | 3245 |

| TL10P | 100 | 190 | 30 | 39 | 250 | 480 | 1981 | 3245 |

| M15B | 150 | 390 | 30 | 39 | 370 | 650 | 1940 | 3290 |

| M15M | 150 | 390 | 20 | 26 | 230 | 650 | 1940 | 3290 |

| T20B | 200 | 700 | 30 | 39 | 425 | 480 | 2183 | 3930 |

| T20P | 200 | 700 | 30 | 39 | 425 | 480 | 2183 | 3930 |

| T20M | 200 | 700 | 30 | 39 | 410 | 480 | 2183 | 3930 |

| TS20M | 200 | 540 | 25 | 33 | 85 | 800 | 1435 | 2750 |

| MX25B | 200/250 | 900 | 25 | 33 | 1000 | 920 | 2900 | 3400 |

| M30 | 300/350 | 1400 | 25 | 33 | 1400 | 1150 | 3100 | 5220 |

| TL35B | 300/350 | 1800 | 30 | 39 | 2200 | 1180 | 3218 | 6400 |

Plate characteristics

The "chocolate" shunt area is one of the many patents for the Afala plate heat exchanger. Its unique structure has achieved:

The uniform distribution of the flow rate removes the dead zone of the flow rate, thus avoiding the corrosion caused by the accumulation of dirt, and at the same time improving the utilization rate of the heat transfer area of the plate.

The same kind of fluid enters. The exit is parallel to the pipe, which simplifies the installation of the project.

Single plate, simplified maintenance.