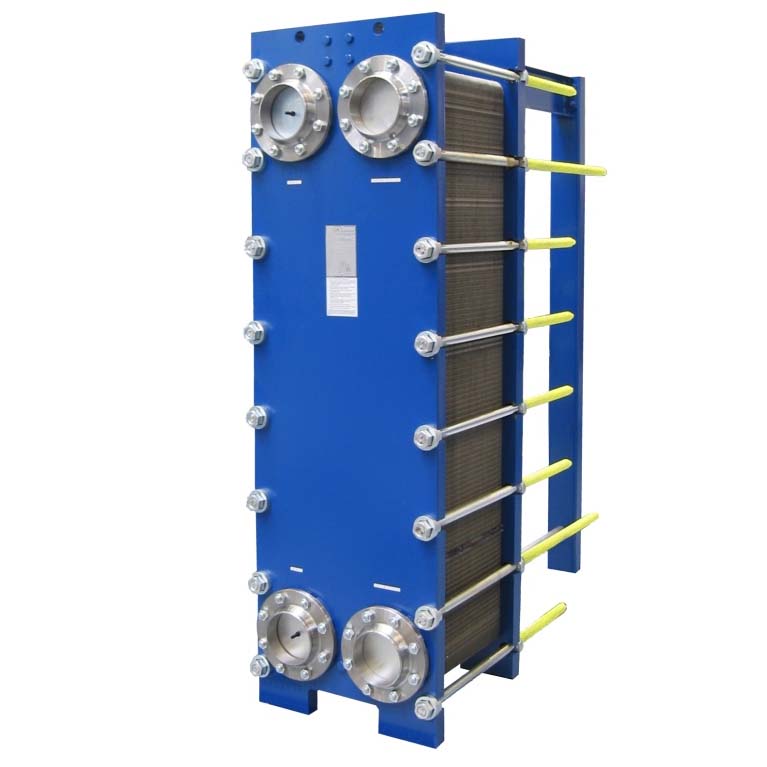

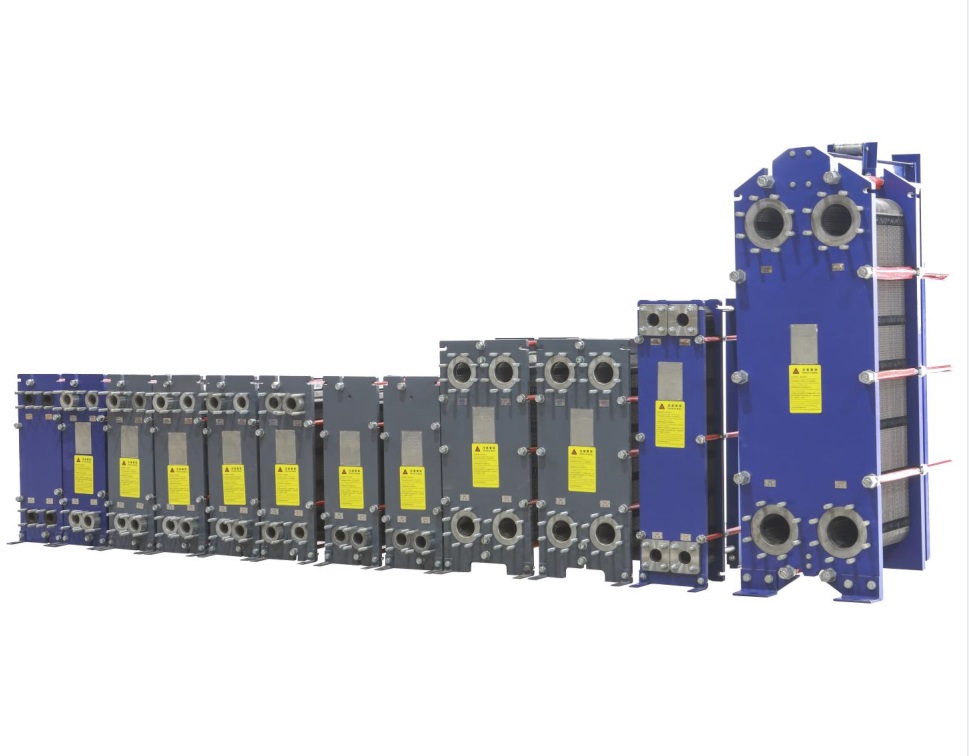

Product Introduction

Sondex Plate Heat Exchanger equivalent completed machine

standard plate heat exchangers are the ideal choice for a wide range of applications across numerous market segments. Innovative technologies and smart design make our standard plate heat exchangers a stellar investment and the go-to choice for standard duties.We have one of the largest plate portfolios in the world and we customize each heat exchanger to meet your exact requirements. The versatile design and high thermal efficiency make them the perfect solution for a wide range of applications.

Features and benefits

- Experience the benefit of an individually customized solution that perfectly matches your requirements and lowers your energy consumption.

- High performance and a low pressure drop eliminate unnecessary burdens on your system and optimize overall system performance.

- We design single-pass solutions when possible, as they are the preferred choice for almost all duties. With all connections on the head you do not need to disconnect the heat exchanger from the piping to perform inspection, cleaning, or service.

- The design results in a compact solution with a small footprint, simple installation, and easy access for maintenance.

Technical specifications

- Conections from DN25 to DN600 (1" to 24")

- Frames designed according to FEA and PED 2014/68/EU (EN13445) and ASME sec VIII, Div. 1 construction standards

- Plate materials: AISI 304/316, titanium, SMO, Hastelloy*

- Gasket materials: EPDM-HT, NBR-HT, Viton*

- Plate lengths up to 5.5 m (18 ft)

- Flow rates up to 7,200 m3/h (31,700 gpm)

- Working pressure up to 35 bar (500 psi)

- Working temperatures from -20 °C to 180 °C (-4 °F to 356 °F)

*Other materials are available upon request.

Applications

- HVAC industry

- Marine/offshore industry

- Dairy/food/beverage industry

- Sugar industry

- Biogas industry

- Pulp and paper industry

- Heavy industry

- Mining industry

- Petrochemical industry

- Chemical industry

Detailed introdution about Sondex plate heat exchanger.

D-Sondex Plate Heat Exchanger Model

Detachable Sondex plate heat exchanger specification

Model

Connection

surface/plate

Plate QTY

QMAX

Surface max

DN

㎡

No.

T/H

㎡

D-S7

50

0.07

76

40

5

D-S14

50

0.15

427

40

59

D-S17

50/65

0.19

609

40

100

D-S18

50/62.5

0.19

609

65

115

D-S21

100

0.22

698

180

146

D-S22

100

0.26

538

165

118

D-S41

150

0.45

670

380

274

D-S42

150

0.46

532

360

223

D-S62

150

0.68

670

380

415

D-S43

200

0.46

695

700

300

D-S65

200

0.68

695

700

450

D-S100

200

1

695

700

695

D-S130

200

1.3

695

700

900

D-S80

300

0.8

930

1600

744

D-S81

300

0.84

930

1600

750

D-S120

300

1.2

930

1600

1115

D-S188

300

1.88

930

1600

1750

300

1.88

930

1600

2210

D-S250

300

2.51

930

1600

2334

D-S200

500

2.06

930

4000

1860

The Table are Sondex Commonly type Pressure Up to 2.5Mpa

Frame type:IS、IT、FT、IG、FS、FG、IC

The heat exchanger with the same angle hole size and width in the SONDEX series heat exchanger has 3-6 types of plates of different heights. Since the position of the corner hole and the aspect ratio of the plate heat exchanger affect the flow of fluids between the plates, it affects heat transfer. Sex, Therefore, SONDEX, a plate with different lengths and widths, meets the requirements of different thermal lengths. (Thermal length θ is the ratio of the temperature difference between the entrance and exit of a heat exchanger medium to the logarithmic average temperature difference of the heat exchanger medium under certain conditions, which is an important parameter of the ability to change the temperature of the heat exchanger.).

SONDEX also designed and produced twin

plates with exactly the same size, only the corrugated depth of the

plate, such as the S41 and S42 models SONDEX heat exchanger, with the

same shape and angle hole size, but the S41 heat exchanger has a width

of 5.4 mm. The S42 heat exchanger has a channel width of 6.9 mm. The

wide channel is more suitable for the uneven flow of fiber, particle or

high viscosity media and hot and cold media. Due to the wide and narrow

channel heat exchangers, SONDEX plate heat exchangers can be designed to

obtain the best inter-plate flow rate, thus achieving a good heat

transfer effect.

Rich tablets make it easy for SONDEX to

provide users with the best solution. For the same working conditions,

SONDEX plate heat exchanger has higher thermal efficiency. The heat

transfer area needed is more economical. This not only saves investment,

but also can easily obtain more reasonable inter-plate flow rate, which

reduces the corrosion and scaling speed of the plate, and extends the

service life of the planter heat exchanger.

Each model of ONDEX has been carefully designed and rigorously tested.

Each type of plate is divided into two

types: adult hard plate(TL) and villain soft plate(TK). The hard plate

has high heat transfer efficiency, high fluid resistance, low heat

transfer efficiency and low fluid resistance. The channel of plate heat

exchanger can be a single soft plate channel, a hard plate channel, and a

soft and hard plate channel can also be a mixture of the above

channels. The optimal design of heat exchanger is obtained by the

scientific ratio of channel.

The SONDEX plate heat exchangers all use

the same side flow, because the design of the guide area is used at the

entrance and exit of the plate, that is, the groove design of the

chocolate island-shaped area at the exit of the corner hole. Ordinary

linear guide slots play a uniform distribution role only for unilateral

fluids, and this chocolate island-shaped groove design can balance the

difference in flow resistance on each flow channel, so that the fluid on

both sides can be obtained in each part of the plate. The relatively

uniform fluid distribution state, Even the wider plate can evenly

distribute the fluid between the plates, which fundamentally improves

the traditional side-flow plate heat exchanger. Because the fluid

distribution state between the plates is different and the flow dead

angle causes the difference in the temperature distribution of the fluid

along the path. And then bring about the adverse effects of reduced

heat transfer efficiency; In addition, this part of the drainage area

also participates in heat transfer at the same time, which improves the

heat transfer area of the SONDEX plate heat exchanger;

Since the above chocolate island-shaped

guide area design ensures the uniform distribution of fluids between

plates, SONDEX adopts the same side-by-side diagonal flow form, making

it easier for users to take over.

The international advanced design and production process make SONDEX plate heat exchanger is the best value for money product.

All SONDEX plate heat exchangers worldwide

are made from 6 hydraulic presses at the Danish SONDEX plant, one of

which has a capacity of 20,000 T and is the largest hydraulic compressor

in Europe. It is specifically used to process large plates above DN400.

Due to the large capacity of the press and advanced stamping

technology, each SODNEX plate pressed is very flat and has no stress

deformation at all. The surface roughness of the stamping sheet is the

same as that of the original sheet, and it has a very high quality

uniformity. The SONDEX sheet is fully in line with the quality

requirements of the food hygiene board. The friction resistance of the

fluid is reduced, the scale is not easy to be scaled, and the point

erosion is not easy to occur, ensuring the stable and efficient

operation of the SONDEX heat transfer equipment.

The difference of body distribution and

flow dead angle results in the difference of temperature distribution of

fluid along the course, which leads to the adverse effect of decreasing

heat transfer efficiency. In addition, this part of the drainage area

also participates in heat transfer at the same time, which improves the

heat transfer area of the SONDEX plate heat exchanger;

Since the above chocolate island-shaped

guide area design ensures the uniform distribution of fluids between

plates, SONDEX adopts the same side-by-side diagonal flow form, making

it easier for users to take over.

SONDEX plate heat exchanger adopts SONDER

LOCK buckle visco-free gasket as the main seal. Compared with adhesive

pads, non-adhesive pads have the advantages of easy installation and

disassembly, repeatable use, and long life. The buckle connection

designed by SONDEX is a row of protruding buckle structures that are

evenly distributed on the gasket to overfit the hole in the

corresponding position on the plate to ensure that the pad is not

detached from the plate installation or use. In contrast to the

suspension type visco-free gasket, the positioning part of the buckle

gasket is not in contact with the fluid in the heat exchanger, thus

preventing the positioning hook of the hanging gasket from being damaged

due to fluid contact and long-term erosion., It affects the sealing

ability. It can be said that the buttoning is the most advanced

structure in the visco-free mat. However, due to the need for accurate

coordination of the structure, a higher requirement is put forward for

the machining accuracy of the plate and the gasket, that is, the

position of all the small holes on the plate and all the buckles of the

gasket must be accurate, otherwise the deviation of any one position

will cause waste. The average manufacturer can not reduce the waste rate

and therefore does not want to adopt this structure.

SONDEX plate heat exchanger gaskets can be used according to the user's different needs, NBR, EPDM, SILON fluorine rubber, etc.. In addition, SONDEX has introduced EPDM HT gaskets and NBRHT gaskets that can withstand high temperatures. EPDM HT high-temperature gaskets can withstand high temperatures of 180 °C. The temperature resistance of plate heat exchanger is greatly improved.