Product Introduction

Thermowave plate heat exchangers

Thermowave plate heat exchangers are characterised by the outstanding efficiency in high pressure applications with natural refrigerants,such as CO2 and NH3 .Thermowave products consist of laser welded modules and can be used for any industrial cooling processes requiring low evaporating temperatures.

Special gaskets, developed for this very application, are not only resis-tant against the media flowing in the heat exchanger, but also guarantee the tightness of the plate heat exchanger and thus the safety of your plant.Thanks to its flexible construction taking care of pressure and tempera-ture changes, the Thermowave can be used for applications with a big demand of heat recovery and energy saving. Thus, a new field of applica-tion was opened for special process conditions, also taking into account environmental safety requirements.

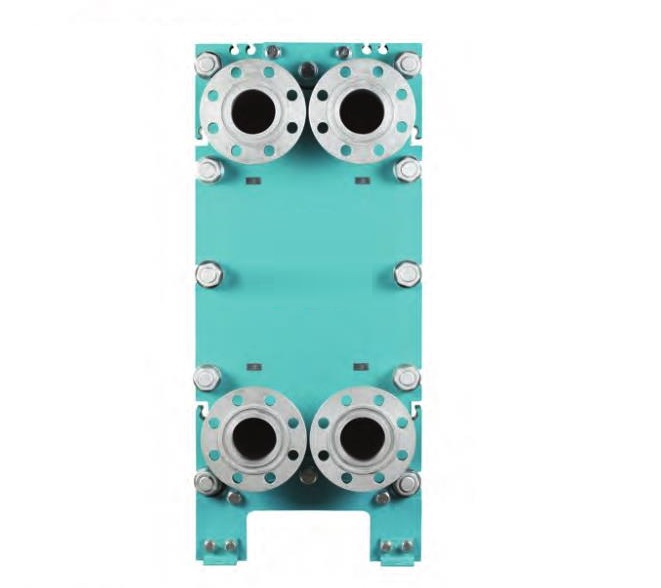

TL 200–250–400–500 Plate heat exchanger

| type width [mm] | height [mm] | connection [DN] | overall | length [mm] |

| TL 200 | 475 | 1122 | 80 | 1750 mm |

| TL 400 | 475 | 1712 | 80 | 1750 mm |

| TL 250 |

550 |

1265 | 100 | 1750 mm |

| TL 500 | 550 | 1750 | 100 | 1750 mm |

Advantages:

– operating pressure 50 bar on CO 2 side (welded)

– suitable for low temperature differences (Cascade)

– high specific thermal efficiency

– compact design, low space requirement, low weight

– modular system offers high degree of flexibility,

capacity adjustment by adding or removing plates

– easy to clean

– excellent fouling resistance due to high turbulence

and smooth faces

– high corrosion resistance

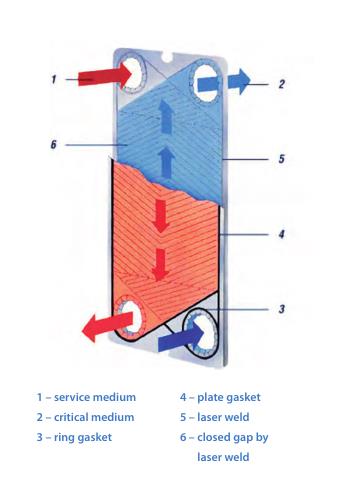

Working principle

Two heat exchanger plates are welded together to a gastight module by means of laser technology. By doing this,a flow channel for the aggressive (or the gasket attacking medium) is built, which is hermetically closed to the outside. Only two ring gaskets, made between two welded modules, are in contact with the aggressive medium.

The other flow channel for the non-aggressive medium is sealed by various elastomer gaskets, depending on the individual application. The gaskets are normally fixed without the need for glue but are also available in the glued-

on-version.

Interleakage between the two media is prevented by a double weld, and a double ring gasket in the port holes.If a leakage occurs for any reason, the leak will be external and easily detected. In spite of the use of welded modules, the proven flexibility of plate heat exchangers is maintained. By adding or changing modules, the heat exchanger capacity can be adjusted to the individual requirements.

The laser welded modules can be used for temperatures from -45° C to +160° C, and for pressures up to 50 bar.

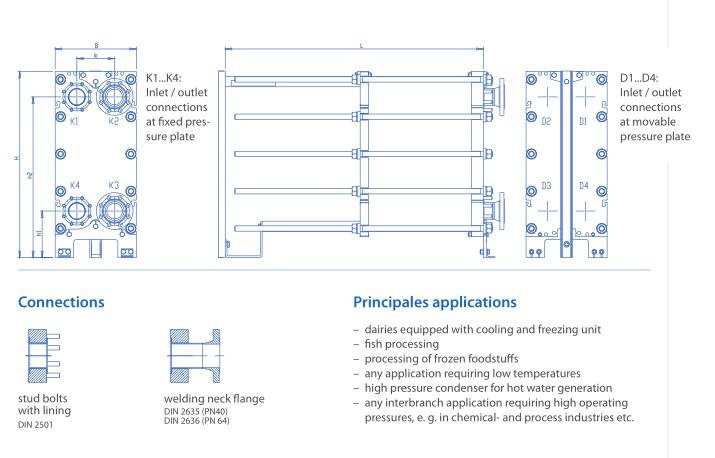

Description of plate heat exchanger

Thermowave plate heat exchangers consist of a number of laser welded modules. The module pack is mounted between a fixed and a movable pressure plate, positioned by an lower and upper carrying bar, and compressed by several tightening bolts. Laser welded modules with various patterns are available for a wide range of applications.

The media can pass the heat exchanger either in cocurrent or countercurrent flow. Depending on the operating condi

tions, medium and temperature-resistant gaskets gaskets are clipped on.The laser welded module, forms a hermetically sealed flow channel to the outside. The transition from one module to another is sealed by a ring gasket made of special materials.

Range of products

Modules with a variety of patterns, variable depths of stamping and different sizes are available.

StandardLine modules

– thermodynamically soft pattern

– high flow rate

– low pressure drop

– wide range of applications

– suitable for viscous fluids and sensitive to shearing

– gentle treatment of products

– corrugation depth of 3,7 mm

PowerLine modules

– thermodynamically hard pattern

– high heat transfer coefficients

– high thermal efficiency

– low hold-up volume

– suitable for homogeneous and low viscous fluids

– corrugation depths from 2,0 to 2,1 mm

Materials

Frame: carbon steel, painted RAL 5018

Connections: stainless steel, carbon steel, elastomeres

Plates: 1.4301, 1.4404

Gaskets: NBR, EPDM, Chloroprene, Butyl

Other materials on request.

Operating parameters

Design temperature: -45° C to 160° C

Design pressure: 50 bar

Connections: DN 80/100

Tests / Standards

ThermoPlus plate heat exchangers can be supplied in

accordance with both local and foreign regulations.